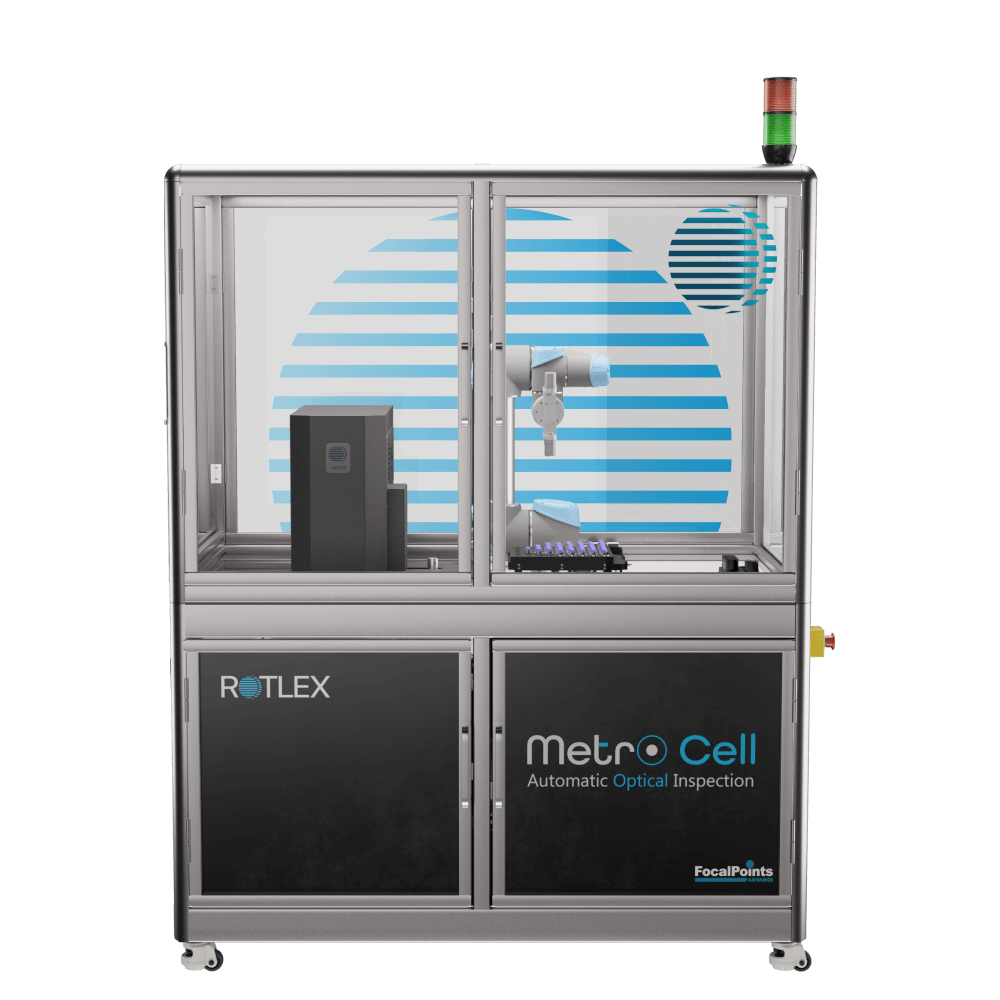

Home / Contact Lenses / Metro Cell

Home / Contact Lenses / Metro Cell

样品测量

Contact Lenses

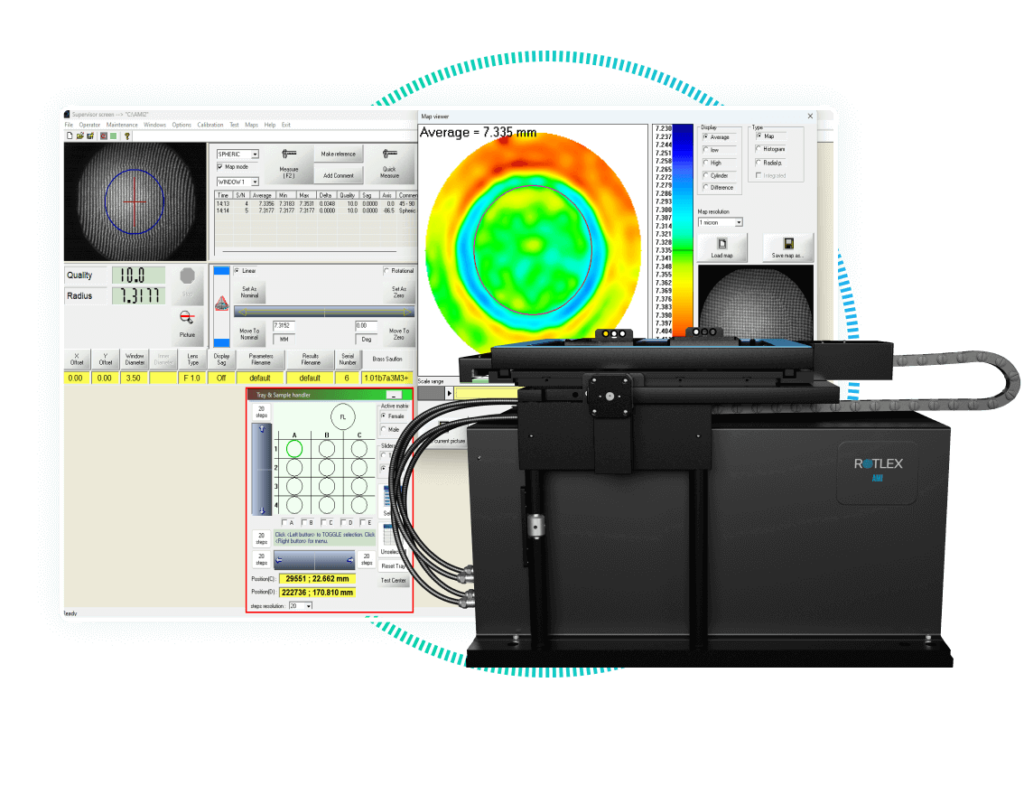

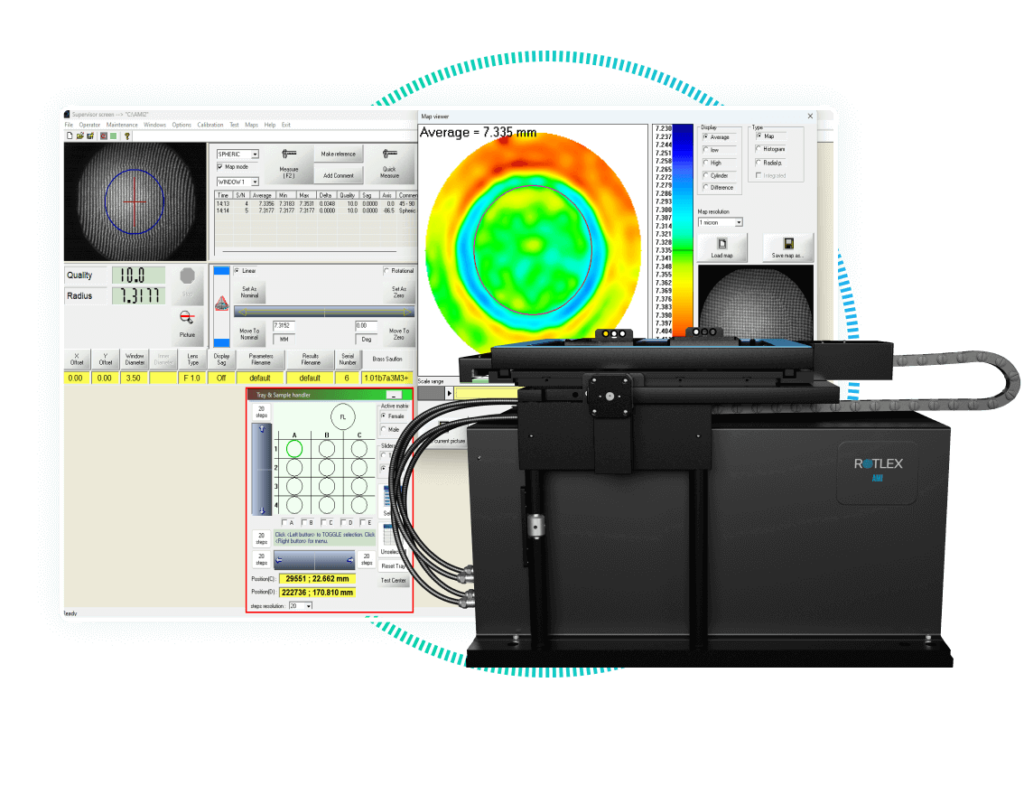

Ami

Contact Lenses

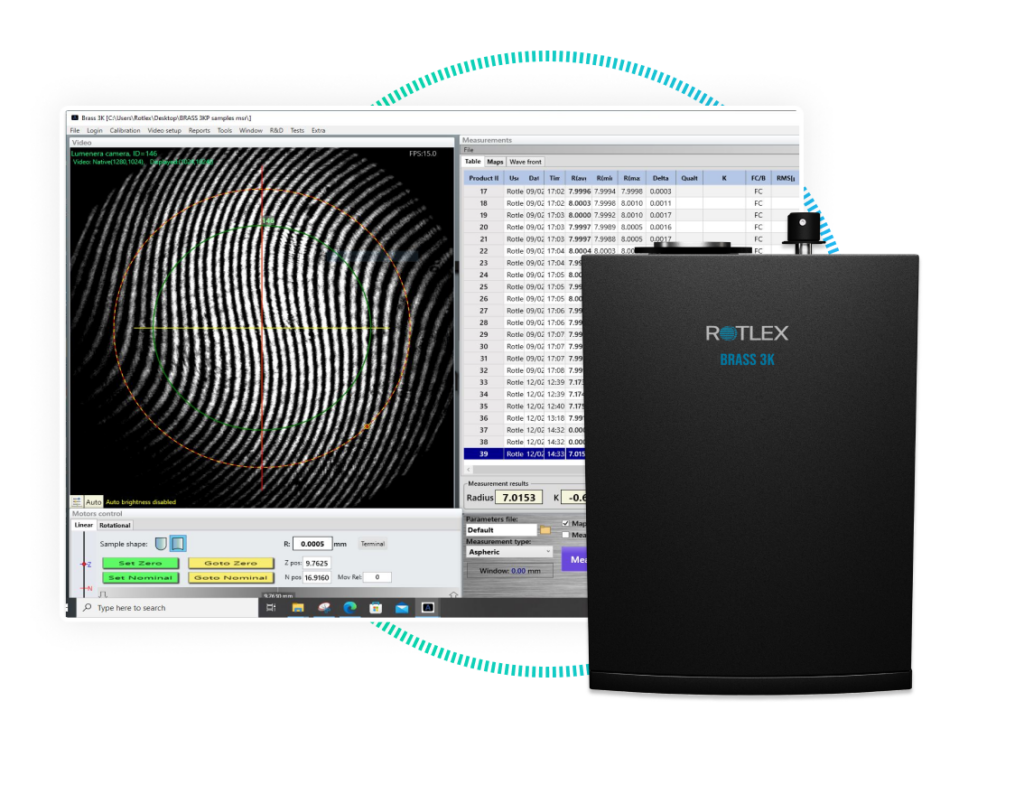

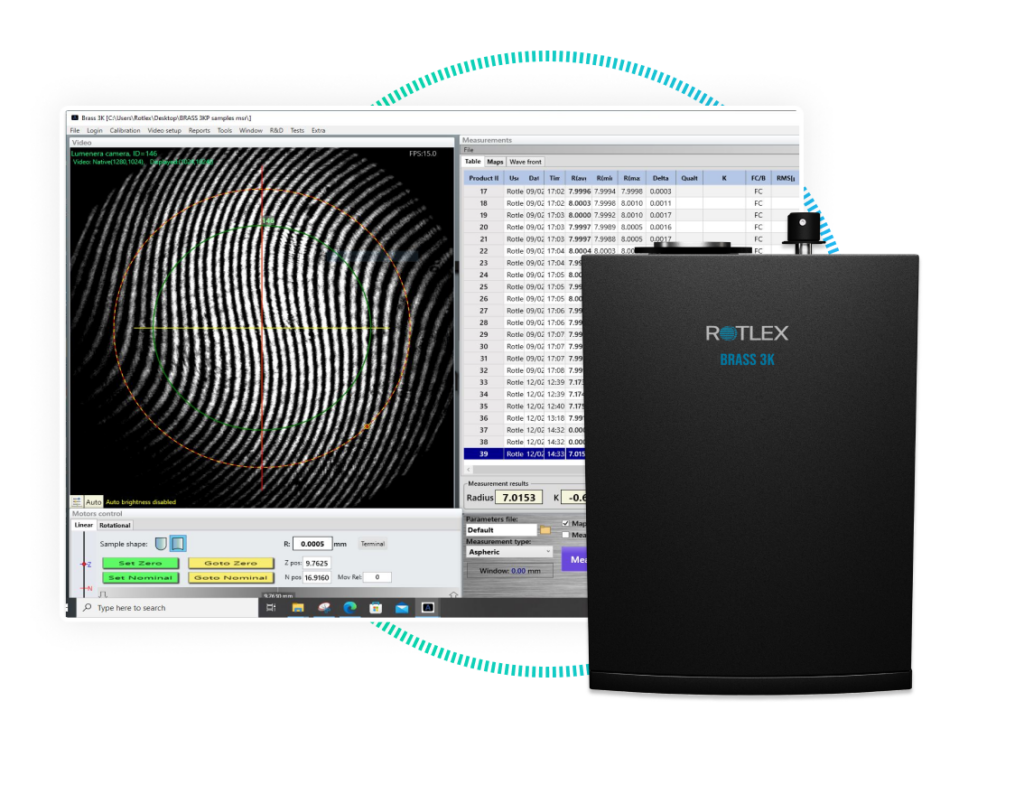

Brass 3k

Contact Lenses

Brass 2000

Contact Lenses

MCT 3000

Contact Lenses

MCT 3000

Contact Lenses

Asis

Contact Lenses

Ami

Contact Lenses

Brass 3k

Contact Lenses

Brass 2000

Contact Lenses

Contest MP

Let Us Assist You in Choosing the Perfect

Solution for Your Needs.

Free Check

Let us know what you plan to send by filling out the sample submission form.

After completing the form, you will receive detailed shipping instructions.

Get a comprehensive report from the specified system upon analysis of your samples.

Fill the form below before you send your lens

Click on any image to enlarge to a full screen mode